FURNACE RECIRCULATION FANS FOR FERROUS AND NON-FERROUS METAL Fabricators

With expertise in both ferrous and non-ferrous metal production applications, Robinson Fans provides custom-engineered solutions to the metal industry to meet existing and emerging high-temperature process fan requirements. Robinson’s technical team can recommend furnace recirculation solutions that meet the specifications of any installation.

We have worked with hundreds of aluminum, steel, and other types of metal production facilities to minimize downtime, and maximize the efficiency of the facility’s air-moving equipment.

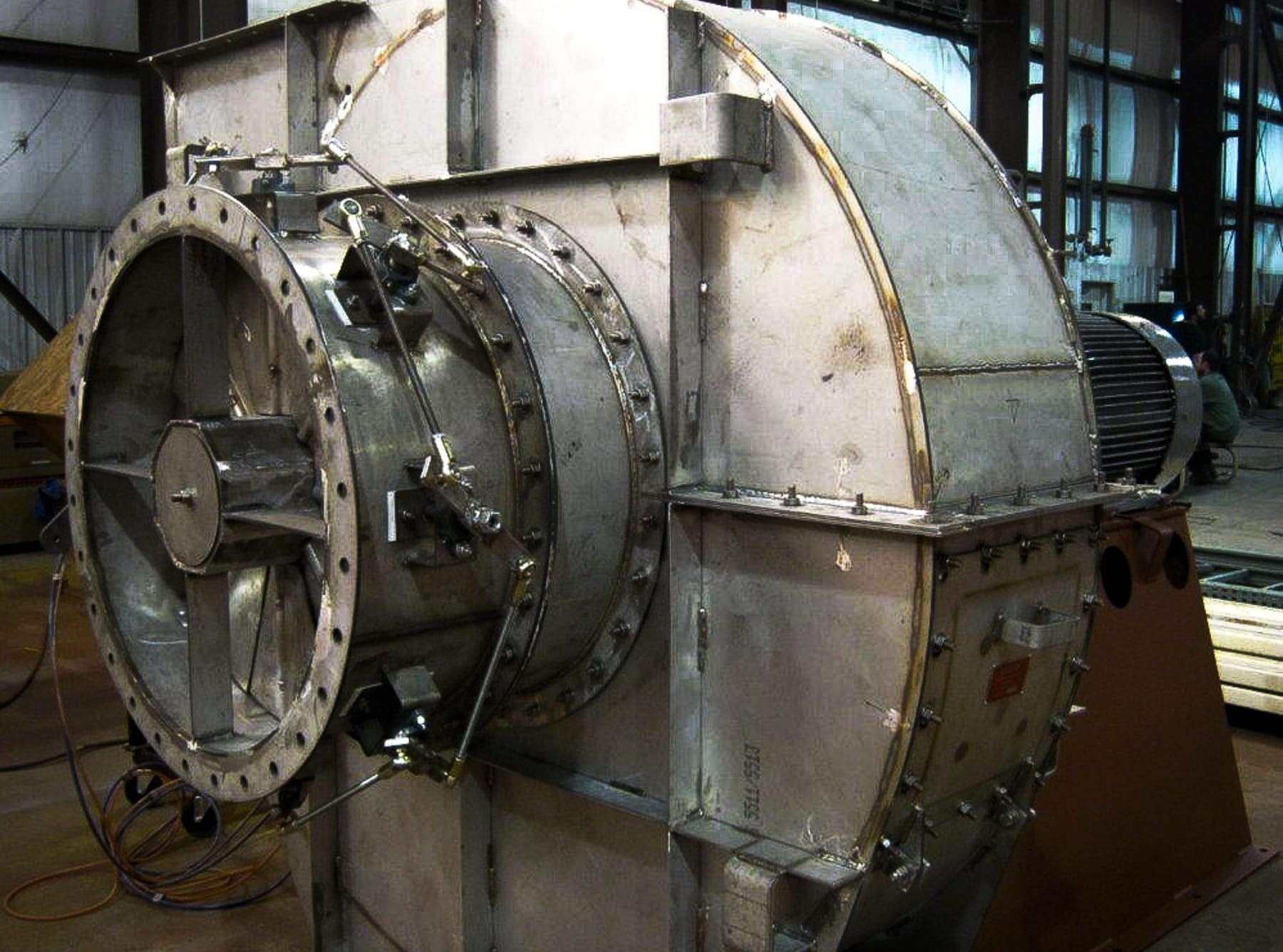

One of 32 fans for a railroad rail quenching process at a steel plant in the western united states — an example of Robinson Fans’ lab air performance testing capabilities. These fans run at 3600 rpm, produce 140 in-wg static pressure and are driven by a 350 horsepower motor.

Case Studies

Furnace Recirculation Repair

An aluminum manufacturing plant was experiencing vibration instability on its ingot preheat furnace recirculation fans. Robinson field technicians ran diagnostics on the furnace’s three identical recirculation fans to determine a reduction in fan speed of the center would avoid vibration interaction instability.

New Baghouse Fan

A metal manufacturing plant experienced total fan unit failure in its baghouse. Robinson Fans crews removed old unit, then installed all new baghouse fan housing, wheel and dampers.

Booster Fan Upgrade

Due to a high volume of particulate, an inlet fan was experiencing erosion on the casing cut-off point and its surrounding scroll area. Robinson designed, manufactured and installed a new pie-shaped booster fan area that can be changed out easily with a spare.

Fan Vibration and Cracking

A steel company had been experiencing severe vibration and cracking of the casing on their coke oven battery scrubber booster fans supplied by a competitor when operated at reduced flow conditions. The Robinson team installed a variable speed controller to regulate flow rate by fan speed.

Boiler House lD Fan Replacement

Faulty roller bearings on a metal fabricator’s boiler house ID fan caused overheating and bent shaft, ultimately leading to a total loss. In a four-day span, Robinson’s team removed the original wheel and shaft, then replaced with a new replacement shaft in a new removable section.