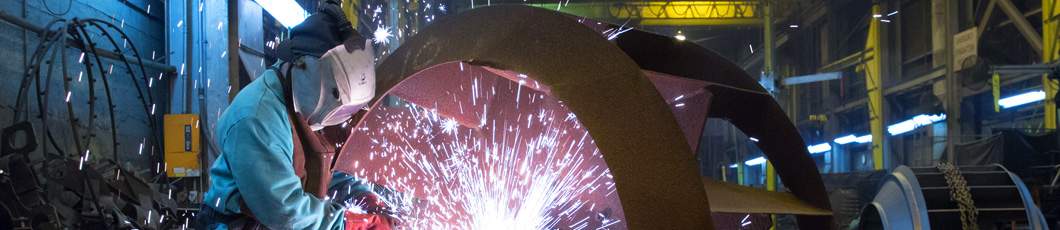

HIGH-TEMPERATURE CENTRIFUGAL PADDLE WHEEL FANS

Performance Ratings

Robinson PW fans are furnished with radial bladed wheels specifically suited for applications involving continuous operation at temperatures from 70° F to 2000° F. PW units are often constructed of special alloy materials for high-temperature service, but are also used for low temperature operations. Other Robinson fans designed for high-temperature applications include axial flow and FC (forward curve) blade series.

Robinson’s PW design is a result of thorough and exacting laboratory testing and documented performance ratings. These ratings were calculated on the basis of complete fan units, including wheel, casing and inlet section.

Components are also furnished separately by Robinson, but the fan unit must be set up with wheel, shaft, casing, inlet and all other components in place to Robinson design specifications to achieve rated performance.

Design Considerations

- PW fans may be furnished as either non-insulated or full-insulated units.

- PW fans are also offered with an insulated plug and non-insulated housing. In this type of construction, the non-insulated housing is usually mounted on the inside wall of the furnace or oven.’

- All Robinson PW Series are available in multiple fan arrangements. Flexibility in design also allows Robinson to offer both round and square plugs to accommodate a wide range of furnace requirements. Other capabilities include gas-tight designs.

- For reliable, efficient service, Robinson has always stressed the importance of preventive maintenance. Fan casings are therefore designed with either plug-type housings or split housings for accessibility to the wheel of servicing and/or removal.

- Optional designs include inlet and outlet flanges, split housings, inspection doors, inlet or outlet dampers and insulation studs.

Quality Control

Dye-penetrant testing, ultrasonic testing, vibration analysis, X-ray testing, computer finite element stress analysis and, in some cases, magnetic-particle inspection are utilized to ensure that the PW series fans meet Robinson’s stringent quality-control requirements. Other steps taken to ensure long fan life include dynamic balancing of the wheel and shaft assembly on independent, computerized equipment. Full-scale mechanical testing is performed on the assembled PW unit (when possible) prior to shipment.

Fan Repair and Field Service

Robinson field service representatives are available for troubleshooting, field balancing and diagnostic inspection of fans and other types of rotating equipment. These personnel supervise certain on-site repairs or, if necessary, determine whether the unit must be factory repaired.

Robinson repairs and rebuilds PW units as well as types of industrial fans, regardless of original manufacturer. In addition to fan repair as a cost-saving alternative, Robinson redesigns and upgrades existing air-moving equipment to increase capacity and improve efficiency.

Industries Served

- Steel

- Mining

- Cement

- Ceramic

- Chemical

- Woodworking